vii. boundary layer flows the previous chapter considered only viscous internal flows. viscous internal flows have the following major bo

VII. BOUNDARY LAYER FLOWS

The previous chapter considered only viscous internal flows.

Viscous internal flows have the following major boundary layer

characteristics:

* An entrance region where the boundary layer grows and dP/dx ≠

constant,

* A fully developed region where:

• The boundary layer fills the entire flow area.

• The velocity profiles, pressure gradient, and w are constant;

i.e. they are not equal to f(x),

• The flow is either laminar or turbulent over the entire length of

the flow,

i.e. transition from laminar to turbulent is not considered.

However, viscous flow boundary layer characteristics for external

flows are significantly different as shown below for flow over a flat

plate:

Fig. 7.1 Schematic of boundary layer flow over a flat plate

For these conditions, we note the following characteristics:

• The boundary layer thickness grows continuously from the start of

the fluid-surface contact, e.g. the leading edge. It is a function of

x, not a constant.

• Velocity profiles and shear stress are f(x,y).

• The flow will generally be laminar starting from x = 0.

• The flow will undergo laminar-to-turbulent transition if the

streamwise dimension is greater than a distance xcr corresponding to

the location of the transition Reynolds number Recr.

• Outside of the boundary layer region, free stream conditions exist

where velocity gradients and therefore viscous effects are typically

negligible.

As it was for internal flows, the most important fluid flow parameter

is the local Reynolds number defined as

where

= fluid density = fluid dynamic viscosity

= fluid kinematic viscosity = characteristic flow velocity

x = characteristic flow dimension

It should be noted at this point that all external flow applications

will not use a distance from the leading edge x as the characteristic

flow dimension. For example, for flow over a cylinder, the diameter

will be used as the characteristic dimension for the Reynolds number.

Transition from laminar to turbulent flow typically occurs at the

local transition Reynolds number, which for flat plate flows can be in

the range of

With xcr = the value of x where transition from laminar to turbulent

flow occurs, the typical value used for steady, incompressible flow

over a flat plate is

Thus for flat plate flows for which:

x < xcr the flow is laminar

x ≥ xcr the flow is turbulent

The solution to boundary layer flows is obtained from the reduced

“Navier – Stokes” equations, i.e., Navier-Stokes equations for which

boundary layer assumptions and approximations have been applied.

Flat Plate Boundary Layer Theory

Laminar Flow Analysis

For steady, incompressible flow over a flat plate, the laminar

boundary layer equations are:

Conservation of mass:

'X' momentum:

'Y' momentum:

The solution to these equations was obtained in 1908 by Blasius, a

student of Prandtl's. He showed that the solution to the velocity

profile, shown in the table below, could be obtained as a function of

a single, non-dimensional variable

defined as

Table 7.1 the Blasius Velocity Profile

with the resulting ordinary differential equation:

and

Boundary conditions for the differential equation are expressed as

follows:

at y = 0, v = 0 f (0) = 0 ; y component of velocity is zero at y =

0

at y = 0 , u = 0 ; x component of velocity is zero at y = 0

The key result of this solution is written as follows:

With this result and the definition of the boundary layer thickness,

the following key results are obtained for the laminar flat plate

boundary layer:

Local boundary layer thickness

Local skin friction coefficient:

(defined below)

Total drag coefficient for length L ( integration of w dA over the

length of the plate, per unit area, divided by 0.5 U2 )

where by definition and

With these results, we can determine local boundary layer thickness,

local wall shear stress, and total drag force for laminar flow over a

flat plate.

Example:

Air flows over a sharp edged flat plate with L = 1 m, a width of 3 m

and

U = 2 m/s . For one side of the plate, find: (L), Cf (L), w(L), CD,

and FD.

Air: = 1.23 kg/m3 = 1.46 E-5 m2/s

First check Re:

Key Point: Therefore, the flow is laminar over the entire length of

the plate and calculations made for any x position from 0 - 1 m must

be made using laminar flow equations.

Boundary layer thickness at x = L:

Local skin friction coefficient at x = L:

Surface shear stress at x = L:

Drag coefficient over total plate, 0 – L:

Drag force over plate, 0 – L:

Two key points regarding this analysis:

1. Each of these calculations can be made for any other location on

the plate by simply using the appropriate x location for any .

2. Be careful not to confuse the calculation for Cf and CD.

Cf is a local calculation at a particular x location (including x = L)

and can only be used to calculate local shear stress at a specific x,

not drag force.

CD is an integrated average over a specified length (including any

) and can only be used to calculate the average shear stress

over the entire plate and the integrated force over the total length.

Turbulent Flow Equations

While the previous analysis provides an excellent representation of

laminar, flat plate boundary layer flow, a similar analytical solution

is not available for turbulent flow due to the complex nature of the

turbulent flow structure.

However, experimental results are available to provide equations for

key flow field parameters.

A summary of the results for boundary layer thickness and local and

average skin friction coefficient for a laminar flat plate and a

comparison with experimental results for a smooth, turbulent flat

plate are shown below.

Laminar Turbulent

for turbulent flow over entire plate, 0 – L, i.e. assumes turbulent

flow in the laminar region

where

local drag coefficient based on local wall shear stress (laminar or

turbulent flow region)

and

CD = total drag coefficient based on the integrated force over the

length 0 to L

A careful study of these results will show that, in general, boundary

layer thickness grows faster for turbulent flow, and wall shear and

total friction drag are greater for turbulent flow than for laminar

flow given the same Reynolds number.

It is noted that the expressions for turbulent flow are valid only for

a flat plate with a smooth surface. Expressions including the effects

of surface roughness are available in the text.

Combined Laminar and Turbulent Flow

Flat plate with both laminar and turbulent flow sections

For conditions (as shown above) where the length of the plate is

sufficiently long that we have both laminar and turbulent sections:

* Local values for boundary layer thickness and wall shear stress for

either the laminar or turbulent sections are obtained from the

expressions for (x) and Cfx for laminar or turbulent flow as

appropriate for the given region.

* The result for average drag coefficient and thus total

frictional force over the combined laminar and turbulent portions of

the plate is given by

(assuming a transition Re of 500,000)

* Calculations assuming only turbulent flow can typically be made for

two cases:

1. when some physical situation (a trip wire) has caused the flow to

be turbulent from the leading edge or

2. if the total length L of the plate is much greater than the length

xcr of the laminar section such that the total length of plate can be

considered turbulent from x = 0 to L. Note that this will over predict

the friction drag force since turbulent drag is greater than laminar.

With these results, a detailed analysis can be obtained for laminar

and/or turbulent flow over flat plates and surfaces that can be

approximated as a flat plate.

Figure 7.6 in the text shows results for laminar, turbulent and

transition regimes. Equations 7.48a & b can be used to calculate skin

friction and drag results for the fully rough regime.

(7.48a)

(7.48b)

Equations 7.49a & b can be used to calculate total CD for combined

laminar and turbulent flow for transition Reynolds numbers of 5x105

and 3x106 respectively.

Example:

Water flows over a sharp flat plate 2.55 m long, 1 m wide, with Um/s.

Estimate the error in FD if it is assumed that the entire plate is

turbulent.

Water: = 1000 kg/m3 = 1.02 E- m2/s

Reynolds number:

with ( or 10% laminar)

a. Assume that the entire plate is turbulent

This should be high since we have assumed that the entire plate is

turbulent and the first 10% is actually laminar.

b. Now consider the actual combined laminar and turbulent flow:

Note that the CD has decreased when both the laminar and turbulent

sections are considered.

{ Lower than the fully turbulent value}

Thus, the effect of neglecting the laminar region and assuming the

entire plate is turbulent is as expected.

Question: Since xcr = 0.255 m, what would your answers represent if

you had calculated the Re, CD, and FD using x = xcr = 0.255 m?

Answer: You would have the value of the transition Reynolds number and

the drag coefficient and drag force over the laminar portion of the

plate (assuming you used laminar equations).

If you had used turbulent equations you would have red marks on your

paper.

Von Karman Integral Momentum Analysis

While the previous results provide an excellent basis for the analysis

of flat plate flows, complex geometries and boundary conditions make

analytical solutions to most problems difficult.

An alternative procedure provides the basis for an approximate

solution which in many cases can provide excellent results.

The key to practical results is to use a reasonable approximation to

the boundary layer profile, u(x,y). This is used to obtain the

following:

a. Boundary layer mass flow:

where b is the width of the area for which the flow rate is being

obtained.

b. Wall shear stress:

You will also need the streamwise pressure gradient for many

problems.

The Von Karman integral momentum theory provides the basis for such an

approximate analysis. The following summarizes this theory.

Displacement thickness:

Consider the problem indicated in the adjacent figure:

A uniform flow field with velocity U approaches a solid surface. As a

result of viscous shear, a boundary layer velocity profile develops.

A viscous boundary layer is created when the flow comes in contact

with the solid surface.

Key Point: Compared to the uniform velocity profile approaching the

solid surface, the effect of the viscous boundary layer is to displace

streamlines of the flow outside the boundary layer away from the wall.

With this concept, we define * = displacement thickness

* = distance the solid surface would have to be displaced to maintain

the same mass flow rate as for non-viscous flow.

From the development in the text, we obtain

Thus, the displacement thickness varies only with the local

non-dimensional velocity profile. Therefore, with an expression for u

/ U , we can obtain * = f().

Example:

Given: determine an expression for * = f()

Note that for this assumed form for the velocity profile:

1. At y = 0, u = 0 correct for no slip condition

2. At y = , u = U correct for edge of boundary layer

3. The form is quadratic

To simplify the mathematics,

let = y/ at y = 0,0 at y = dy = d

Therefore:

Substituting:

which yields

Therefore, for flows for which the assumed quadratic equation

approximates the velocity profile, streamlines outside of the boundary

layer are displaced approximately according to the equation

This closely approximates flow for a flat plate.

Key Point: When assuming a form for a velocity profile to use in the

Von Karman analysis, make sure that the resulting equation satisfies

both surface and free stream boundary conditions as well as has a form

that approximates u(y).

Momentum Thickness:

The second concept used in the Von Karman momentum analysis is that of

momentum thickness -

The concept is similar to that of displacement thickness in that is

related to the loss of momentum due to viscous effects in the boundary

layer.

Consider the viscous flow regions shown in the adjacent figure.

Define a control volume as shown and integrate around the control

volume to obtain the net change in momentum for the control volume.

If D = drag force on the plate due to viscous flow, taking the fluid

as the control volume, we can write

- D = ( momentum leaving c.v. ) - ( momentum entering

c.v. )

Completing an analysis shown in the text, we obtain

Using a drag coefficient defined as

We can also show that

where: (L) is the momentum thickness evaluated over the length L.

Thus, knowledge of the boundary layer velocity distribution u = f(y)

also allows the drag coefficient to be determined.

Momentum integral:

The final step in the Von Karman theory applies the previous control

volume analysis to a differential length of surface. Performing an

analysis similar to the previous analysis for drag D we obtain

This is the momentum integral for 2-D, incompressible flow and is

valid for laminar or turbulent flow.

where

Therefore, this analysis also accounts for the effect of freestream

pressure gradient.

For a flat plate with non-accelerating flow, we can show that

Therefore, for a flat plate, non-accelerating flow, the Von Karman

momentum integral becomes

From the previous analysis and the assumed velocity distribution of

The wall shear stress can be expressed as

(A)

Also, with the assumed velocity profile, the momentum thickness can

be evaluated as

or

We can now write from the previous equation for w

Equating this result to Eqn. A we obtain

or

which after integration yields

or

Note that this result is within 10% of the exact result from Blasius

flat plate theory.

Since for a flat plate, we only need to consider friction drag (not

pressure drag), we can write

Substitute for to obtain

Exact theory has a numerical constant of 0.664 compared with 0.73 for

the Von Karman integral analysis.

It is seen that the Von Karman integral theory provides the means to

determine approximate expressions for

, w, and Cf

using only an assumed velocity profile.

Solution summary:

1. Assume an analytical expression for the velocity profile for the

problem.

2. Use the assumed velocity profile to determine the solution for the

displacement thickness for the problem.

3. Use the assumed velocity profile to determine the solution for the

momentum thickness for the problem.

4. Use the previous results and the Von Karman integral momentum

equation to determine the solution for the drag/wall shear for the

problem.

and 7.3 and does not have to be accounted for separately.

VII-16

TABELA DE QUOTIZAÇÃO – 2021 TABLE OF FEES

TABELA DE QUOTIZAÇÃO – 2021 TABLE OF FEES  FULL D’AUTORITZACIÓ PER LA RECOLLIDA DE L’INFANT JO …………………………………………………

FULL D’AUTORITZACIÓ PER LA RECOLLIDA DE L’INFANT JO ………………………………………………… C HILDREN AND FAMILY SERVICES

C HILDREN AND FAMILY SERVICES QUALNET 50 TUTORIAL PART 1 INSTALLATION TODO

QUALNET 50 TUTORIAL PART 1 INSTALLATION TODO ROZDZIAŁ 4 MAŁGORZATA DĄBROWSKA UNIVERSITIES IN A KNOWLEDGEBASED SOCIETY

ROZDZIAŁ 4 MAŁGORZATA DĄBROWSKA UNIVERSITIES IN A KNOWLEDGEBASED SOCIETY REQUISITOS PARA LA PRESENTACIÓN A DESEMPEÑO DOCENTE 2020

REQUISITOS PARA LA PRESENTACIÓN A DESEMPEÑO DOCENTE 2020  CCSDS FILE DELIVERY PROTOCOL (CFDP)— NOTEBOOK OF COMMON INTERAGENCY

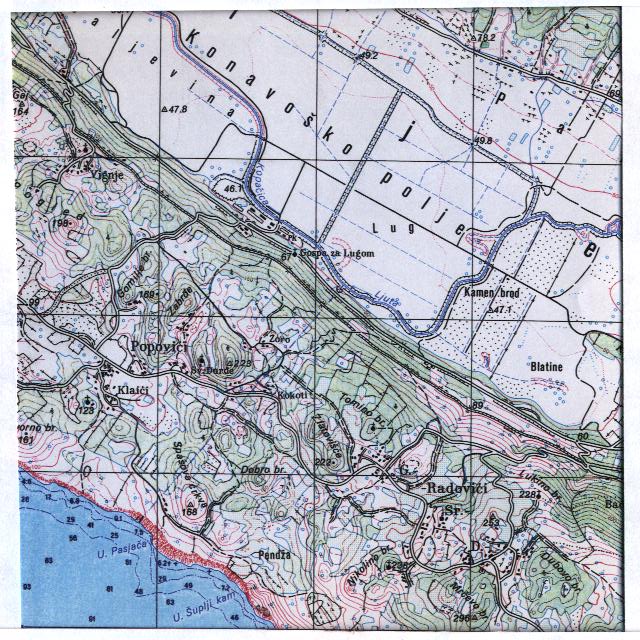

CCSDS FILE DELIVERY PROTOCOL (CFDP)— NOTEBOOK OF COMMON INTERAGENCY FLOODS IN KARST AREA – CASE STUDY CROATIA

FLOODS IN KARST AREA – CASE STUDY CROATIA