pulling small tubing and optical fibers on the p-2000/f the sutter instrument p-2000 pipette puller was designed to allow the pulling

Pulling Small Tubing And Optical Fibers On The P-2000/F

The Sutter Instrument P-2000 pipette puller was designed to allow the

pulling of high melting point glasses such as fused silica. The

standard P-2000/G is a very versatile instrument, capable of pulling a

wide variety of tapers and tips sizes from all standard glass types in

sizes from 0.5 mm to 1.5 mm in diameter. The use of smaller diameter

glass is only limited by the system used to clamp the glass.

The glass is clamped by screw pressure in a V-shaped groove cut in the

glass carrier. If the glass diameter is too small, the glass will lay

in the groove below the surface of the carrier bar, and the clamping

pad will not be able to apply pressure against the glass. The simple

solution for this problem is to use carrier bars with a smaller groove

cut in them. Sutter Instruments has supplied pullers fitted with such

carrier bars on request for many years. The development of the P-2000,

with the ability to draw fused silica, has led to increased interest

in drawing small diameter tubing and optical fibers. Because of this

interest, Sutter Instruments now produces a version of the P-2000 that

is adapted for small diameter glass. This version can be specified as

the P2000.F. The version for larger diameter glass has been renamed

the P2000/G.

The P2000/F can also be used with larger diameter tubes, and each

P2000/F is first tested with 1 mm tubes extensively before final

adjustments and testing with 125 micron fused silica optical fiber.

The only real disadvantage of the P2000/F for larger diameter glass is

that more care is required to properly clamp larger tubes in the small

V-grooves of the P2000/F. The position of the center of the glass is a

function of the glass diameter, so some adjustment of the optics may

be desirable when changing the diameter of the glass to be pulled. In

most cases adjustment of program values will be all that is required.

The P-2000/F has the same basic features as the standard P-2000/G. The

power to melt the glass comes from a CO2 laser embedded in the unit.

The laser output power is servo controlled. The output power level is

programmed by the user. Each unit is set up to provide a maximum power

of 10 Watts CW, which is enough to melt fused silica of up to 1.5 mm

in diameter. The optical system of the P-2000 concentrates the laser

output so that small diameter fused silica such as optical fibers may

be drawn using less than 1/4 of the rated power.

The laser beam is directed at the glass by reflection off a scanning

mirror. The user can select, by entering a program value, the scan

pattern that is used. This allows the user to determine the

distribution of heating along the length of the glass, which in turn

controls the geometry of the taper.

In the P-2000 the laser system has been carefully integrated with the

technology derived from our long experience with conventional pullers.

It is obvious that a glass puller needs a means of heating the glass

to a suitable working temperature and a means of applying force to

draw the glass. In most cases, heat is applied while the glass is

under a low tension or pull. When the glass begins to soften and

yield, the heating is ended and a strong pulling force is applied,

drawing the glass apart.

In the P-2000 the weak pull is provided by gravity. The softening of

the glass is determined by measuring the velocity at which the glass

is being drawn out by the weak pull. When the velocity reaches the

level programmed by the user, the next stage of the pulling process

begins. At this point the user has the option of turning off the laser

and then, after a delay, turning on the hard pull or turning on the

hard pull immediately and delaying the turn-off of the laser. This

provides a very sensitive control over the heat content of the glass

during the hard pull.

Using this version of the P-2000, a wide range of tip sizes and taper

lengths may be produced. We have drawn fiber tips ranging from less

than 10 nanometers in diameter up to more than 0.5 micrometer in

diameter. Each unit is programmed and tested to produce tips of about

40 nanometers in diameter. These tips appear to be flat on the end.

T

he following sample SEM photos show a 60nm fiber tip and a 40nm fiber

tip (after subtracting for the 10nm gold coating put on for viewing

the tips under the SEM) produced on a P-2000 set up to pull optical

fibers.

One Digital Drive, Novato CA 94949

tel: (415) 883-0128 fax: (415) 883-0572 email: [email protected]

POLÍTICAS PARA LAS MUJERES UN DESAFÍO PARA LA IGUALDAD

POLÍTICAS PARA LAS MUJERES UN DESAFÍO PARA LA IGUALDAD ECCLESIASTICAL ENDORSEMENT FOR VETERANS AFFAIRS CHAPLAINCY APPLICANT INFORMATION

ECCLESIASTICAL ENDORSEMENT FOR VETERANS AFFAIRS CHAPLAINCY APPLICANT INFORMATION COLUMBARIO SAN MIGUEL (NUESTRAS RESPUESTAS SE HALLAN EN LA

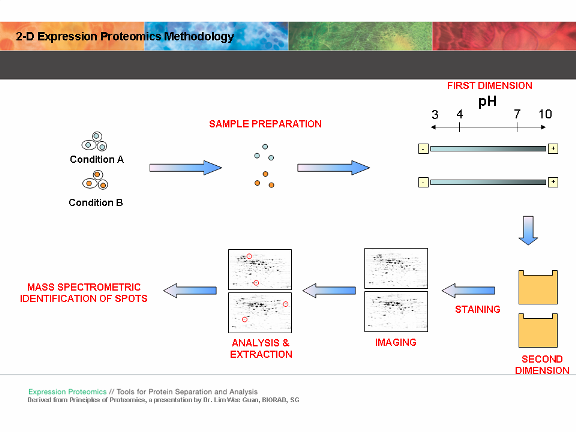

COLUMBARIO SAN MIGUEL (NUESTRAS RESPUESTAS SE HALLAN EN LA VERMONT GENETICS NETWORK PROTEOMICS LAB MANUAL INSTRUCTION TEAM

VERMONT GENETICS NETWORK PROTEOMICS LAB MANUAL INSTRUCTION TEAM İŞ SAĞLIĞI VE GÜVENLİĞİ POLİTİKASI İŞ AMAÇLARIMIZ KADAR

İŞ SAĞLIĞI VE GÜVENLİĞİ POLİTİKASI İŞ AMAÇLARIMIZ KADAR GRAD LEPOGLAVA POVJERENSTVO ZA POLJOPRIVREDU I RURALNI RAZVOJ ANTUNA

GRAD LEPOGLAVA POVJERENSTVO ZA POLJOPRIVREDU I RURALNI RAZVOJ ANTUNA SECRETARIA DE HACIENDA Y CREDITO PÚBLICO SERVICIO DE ADMINISTRACIÓN

SECRETARIA DE HACIENDA Y CREDITO PÚBLICO SERVICIO DE ADMINISTRACIÓN TRES OBRAS LITERARIAS LA CELESTINA (ADAPTACIÓN JUVENIL) ………………………

TRES OBRAS LITERARIAS LA CELESTINA (ADAPTACIÓN JUVENIL) ……………………… DIFUSOR COMBINADO KWB TEXTOS DE ESPECIFICACIÓN DIFUSOR COMBINADO PARA

DIFUSOR COMBINADO KWB TEXTOS DE ESPECIFICACIÓN DIFUSOR COMBINADO PARA NAME SID NAME OF STUDENT AT YOUR

NAME SID NAME OF STUDENT AT YOUR